70mm 100mm 120mm Alüminyum Bakır Skived Fin Yığılmış ısı lavabosu GPU için

Ürün ayrıntıları:

| Menşe yeri: | Dongguan , Guangdong, Çin |

| Marka adı: | Uchi |

| Sertifika: | SMC |

| Model numarası: | tırtıklı kanatlı ısı emici 04 |

Ödeme & teslimat koşulları:

| Min sipariş miktarı: | 100 adet |

|---|---|

| Fiyat: | pazarlık edilebilir |

| Ödeme koşulları: | Banka havalesi, paypal, Western Union, MoneyGram |

| Yetenek temini: | Ayda 50000000pcs |

|

Detay Bilgi |

|||

| İşleme Hizmeti: | Kesme, Delme, Rulo Açma, Bükme, Delme | Öfke: | T3 ~ T8 |

|---|---|---|---|

| Ambalaj: | PE ÇANTA karton | Hoşgörü: | ±%1 |

| Standart: | Orta ve yüksek kaliteli alüminyum soğutucu | Genişlik: | müşteri talebine göre |

| Malzeme: | Alüminyum | Teknoloji: | CNC ve Skiving |

| Kalınlık: | 0,5-2,5 mm | Başvuru: | Endüstriyel, Kapı, Çerçeveleme, LED Isı Emici |

| Vurgulamak: | Alüminyum bakır kaydırılmış ısı lavabosu,Yığılmış GPU ısı alıcı,70mm 120mm sıvı soğutma plağı |

||

Ürün Açıklaması

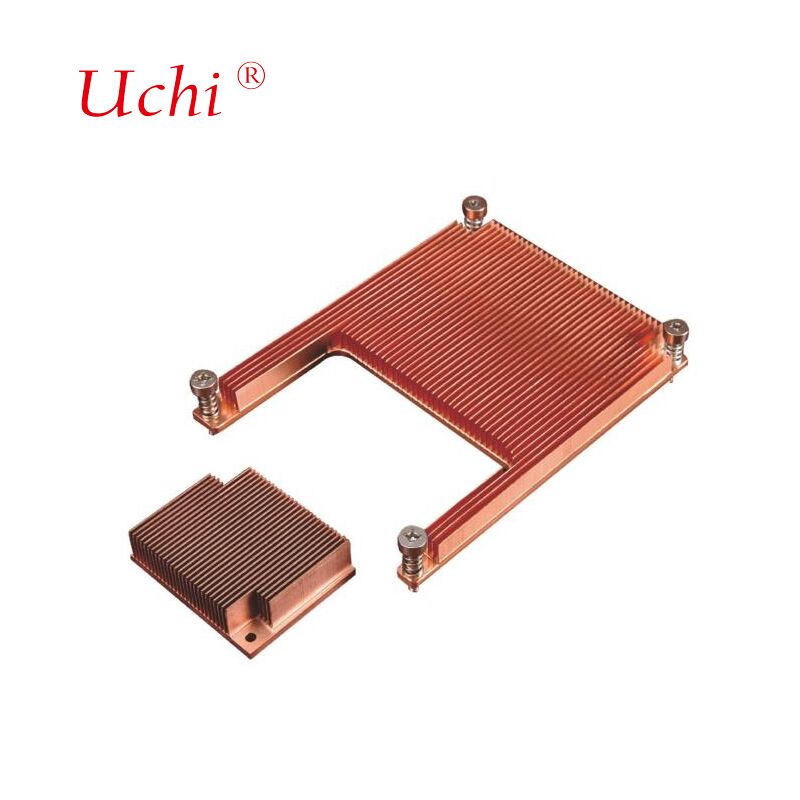

GPU'lar için Alüminyum Bakır Skived Fin Yüklü Isı Lavabosu

Özellikle elektronik ve endüstriyel ekipmanlarda GPU soğutma uygulamaları için tasarlanmış yüksek performanslı 70mm, 100mm ve 120mm alüminyum bakır skived fin yığılmış ısı lavaboları.

Ürün Özellikleri

| Türü | Kayma kanatlı ısı fıskiyesi |

| Malzeme | Alüminyum, bakır |

| Yüzey Tedavisi | Kum püskürtme, cilalama, anodlama, kaplama |

| Uygulama | Elektronik ve endüstriyel ekipman |

| MOQ | Örnek ve küçük siparişler kabul edilir |

| Teslim Zamanı | 21-25 gün içinde |

| Kalite | % 100 tam denetim |

| Paketleme | Karton + ahşap kutu |

| Hizmet | OEM ODM özelleştirmeyi kabul edin |

Doğal Soğutma Teknolojisi

Doğal soğutma, sıcaklığı çevresel havaya verimli bir şekilde aktarmak ve dağıtmak için yüksek termal iletkenliğe sahip malzemeler kullanan en yaygın uygulanan ısı dağılma yöntemini temsil eder.Bakır-alüminyum ısı lavabolarımız, alüminyum alaşımlı dışkılanmış bileşenler, işlenmiş ısı dağılımı parçaları ve alaşımlı döküm bileşenleri, standart rüzgar hızı gereksinimleri olan uygulamalarda optimal performans sağlar.

Teknik Yenilik

Yüksek verimli ısı dağılımı uzmanları olarak doğal soğutma teknolojisi araştırma ve geliştirme alanında önemli atılımlara ulaştık.

Gelişmiş Kayak Fin Teknolojisi

Bağımsız olarak geliştirilen yüksek yoğunluklu kayma kanat teknolojimiz, ultra ince kanat, ultra ince kanat mesafesi ve ultra yüksek kanat boyut oranlarına sahip ısı sink yapıları üretiyor.Bu yenilik, ekleme tipi ısı dağılımı teknolojisini tamamen değiştirir., aşağıdakileri içeren üstün avantajlar sunuyor:

- Daha büyük ısı dağılımı alanı

- Tek seferlik şekillendirme işlemi

- Profillerin %100 ısı iletkenliği kullanımı

- Geliştirilmiş ısı dağılımı performansı

Sürtünme kaynaklı yenilik

Daha önce profillerin ultra geniş yapı ısı dağılım gereksinimlerini karşılamasını kısıtlayan teknik sınırlamaların üstesinden gelmek için uluslararası çapta gelişmiş sürtünme kaynak teknolojisini kullanıyoruz.Bu atılım daha yüksek ısı dağılımı gücünü ve daha büyük ısı dağılımı yapılarını mümkün kılıyor.

Endüstri Uygulamaları

Yüksek End Üretim

- Yarım iletken ve çip imalatı:3 boyutlu yığma gibi gelişmiş ambalaj teknolojilerinde ısı birikimi ile ilgilenir

- AI Bilgisayar/Bilgi Merkezleri:Yüksek performanslı yongalarda yükselen ısı akışı yoğunluğunu yönetir

- Havacılık:Aşırı sıcaklık ve vakum ortamlarında termal yönetimi sağlar

Günlük Yaşamda Kullanılan Ürünler

- Dijital cihazlar:Bilgisayarlar, cep telefonları ve oyun konsolları için iç soğutma modülleri

- İletişim cihazları:Yüksek hızlı veri aktarımında istikrar sağlayan büyük ısı alıcıları

- Ev aletleri:Kompresörler ve kondansörler için verimli ısı dağılımı

- Aydınlatma cihazları:LED lambasının verimliliği ve uzun ömrü için optimize edilmiş termal tasarım

- Yeni Enerji Araçları:Optimal çalışma sıcaklıkları için sofistike sıvı soğutma sistemleri

Üretim kapasitesi

Gelişmiş Ekipmanlar

Kalıp atölyemizde aşağıdakiler de dahil olmak üzere kapsamlı üretim yetenekleri bulunmaktadır:

- 22 elektrikli boşaltma makinesi (bu da 2 MAKINO ayna EDM makinesi)

- 9 tel kesme EDM makinesi (3 Seibu, 1 Sodick Japonya'dan ithal edildi)

- 7 kıvılcım erozyon makinesi, 10 öğütme makinesi, 2 freze makinesi, 1 torna

Teknik özellikler

- Masa boyutu: 500×350 mm

- Hızlı geçiş hızı: 5000 mm/dakika

- İş parçasının maksimum ağırlığı: 500 kg

- Elektrot ağırlığı: 50 kg

Hassas İşleme

SuperSpark4 ve IES (Akıllı Uzman Sistemi) teknolojilerini kullanarak, makine doğruluğunu arttırırken EDM süreçlerini istikrarlandırmak için gelişmiş uyarlanabilir güç kaynağı ve atlama kontrolü sağlıyoruz.Ultra yüzey ve ultra uç jeneratör teknolojilerimiz olağanüstü yüzey finişi ve metalürjik kaliteyi sunar..

Ürün Uygulamaları

Kalite güvencesi

Katı test ekipmanlarıyla katı kalite standartlarını koruyoruz:

- 1 Koordinat Ölçme Makinesi

- 1 projeksiyon cihazı

- 2 su yüksek basınçlı test makinesi

- 4 ısı direnci test makinesi

- 2 sıvı sızıntısı test makinesi

Müşteri Hizmetine Bağlılık

- Tüm sorulara hızlı yanıt

- Kalite garantisi ile rekabetçi fiyatlandırma

- Verimli üretim planlaması

- En iyi ulaşım çözümleri

- Kapsamlı teknik destek

Sıkça Sorulan Sorular

Bir ticaret şirketi mi yoksa üretici misiniz?

Uzman bir ısı alıcı ve su soğutma plaka üreticisiyiz. Geniş bir deneyime ve güçlü bir teknik ekibe sahip, otomatik ve mekanize üretime sahiptir.

Daha önce hangi bölgelere mal ihraç ettiniz?

Toplam üretimimizin %60'ı Japonya, Hindistan, İngiltere, Kanada, ABD ve Brezilya'ya ihraç ediliyor.

Kaç çalışanınız var?

Satış, satın alma, mühendislik, kalite kontrolü, depo ve üretim departmanlarında yaklaşık 100 çalışan.

Eğer tasarımla anlaşırsak örnekler verebilir misiniz?

Evet, seri üretimden önce onay için örnekler ve gerekirse teknik çizimler sağlıyoruz.

Ne tür paketleme yöntemleri kullanıyorsunuz?

Normal karton ve sıkı kanatlı kumaş veya ahşap kartonlarla taşıma sırasında en iyi koruma için özel ambalaj.

Ürün sorunları için teknik destek veriyor musunuz?

Tüm ürünler gönderilmeden önce tam olarak denetlenir. Herhangi bir sorun için, derhal teknik çözümler sağlarız.

Bu ürün hakkında daha fazla bilgi edinmek istiyorum